Mabenyane a Laser Welding Machine - Arohaneng Water Chiller

Kenyelletso ea Sehlahisoa

Mochini oa ho roala mabenyane oa laser ke mofuta o mocha oa mokhoa oa ho tjheseletsa, haholo-holo bakeng sa indasteri ea ho roala mabenyane a laser, hape e loketse ho tjheseletsa ha likarolo tse nepahetseng tsa lisebelisoa tse tšesaane tse nang le marako.E ka hlokomela tjheseletsa butt, ho tiisa welding, welding spot, overlap welding, joalo-joalo, bophara ba weld bo nyane, karolo ea karolo e phahame, 'me mocheso o amehang o nyane, deformation e nyane, lebelo la welding ka potlako, seam e boreleli le e ntle ea welding.Lihlopha tse nyenyane tsa solder, ha ho na porosity le matla a phahameng.

Mochini oa ho roala mabenyane oa laser o nka moralo oa ergonomic, moralo oa ponahalo oa setsebi, o nang le sistimi e khethehileng ea ho shebella microscope ea cross cursor, e nang le sesebelisoa sa filthara ea elektroniki se lebelo le holimo, se ka sireletsang mahlo a basebelisi.Phello e ntle ea welding, lisebelisoa tse tsitsitseng le tse ka tšeptjoang, tekanyo e tlaase ea ho hlōleha.

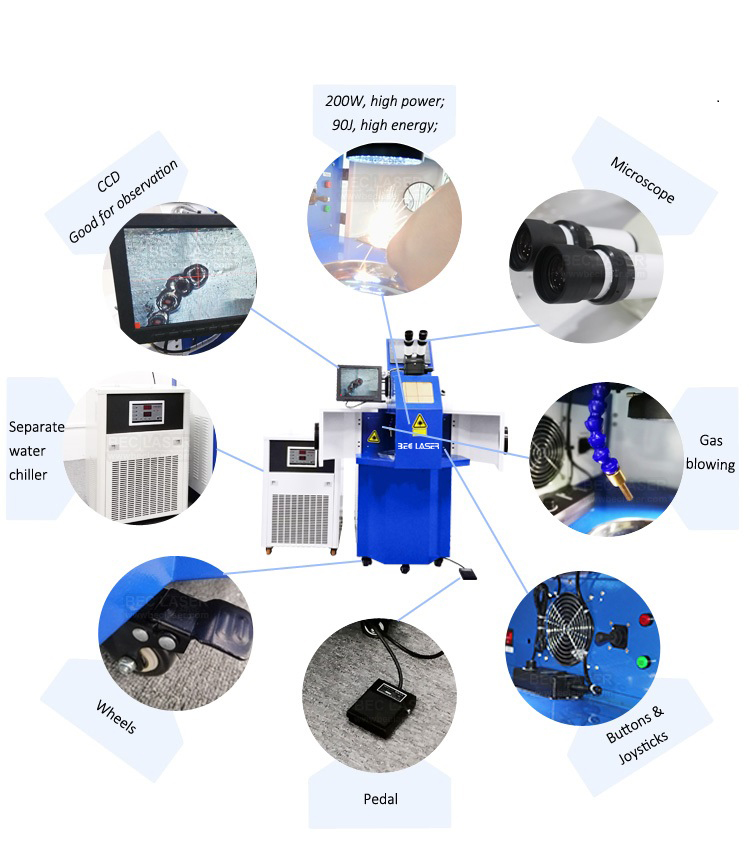

Likaroloana

1. Ka ntle chiller e loketse bakeng sa tlhokomelo le mocheso o motle oa ho senya.

2. Matla a phahameng le matla a phahameng, a loketse lintho tse bonahalang tse phahameng tse kang khauta, silevera le koporo.

3. Touch skrine segokanyimmediamentsi sa sebolokigolo ho fana ka bonolo taolo tshebetso bakeng sa basebedisi ba.

4. Boleng bo phahameng, lihora tse 24 tsa bokhoni bo tsoelang pele ba ho sebetsa, bophelo ba cavity ke lilemo tse 8 ho isa ho tse 10, bophelo ba lebone la xenon ka makhetlo a fetang limilione tse 8.

5. Moralo o bonolo oa basebelisi, o tsamaellana le ergonomic, o sebetsa lihora tse telele ntle le mokhathala.

6. Sistimi ea microscope ea 10X e thehiloeng ho bopula-maliboho ba tšebeliso ea mokhoa o phahameng oa ho shebella oa CCD ho netefatsa phello ea letheba ponahalong.

7. Matla, bophara ba pulse, maqhubu a ka fetoloa ka har'a mefuta e mengata ho finyella liphello tse fapaneng tsa welding.

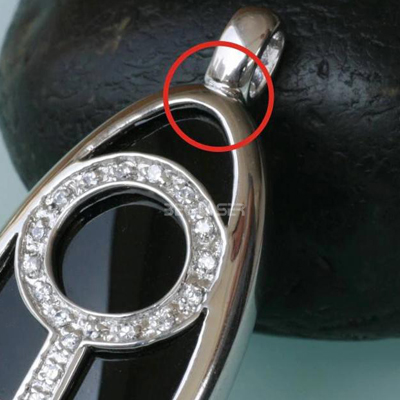

Kopo

Mochini oa ho roala mabenyane / meno a laser tjheseletsa ka ho khetheha bakeng sa mabenyane a laser welding ea sehlahisoa, haholo-holo a sebelisoang ka khauta, silevera, platinum, koporo, titanium, tšepe e sa hloekang le lisebelisoa tse ling tsa tšepe.

Joalo ka reng, masale, sefaha, sefaha, sekotwana sa molala, li-cuffs le mabenyane a mang a tšepe.

Mochini ona oa welding oa laser o sebelisoa haholo ho mabenyane, meno, likarolo tsa elektroniki, likhokahano, mesebetsi ea matsoho le liindasteri tse ling, lebala la matšoao a papatso, tebello ea 'maraka e ntle.

Mekhahlelo

| Mohlala | BEC-JW200S |

| Matla a Laser | 200W |

| Laser Wavelength | 1064 nm |

| Mofuta oa laser | ND: YAG |

| Max.Matla a Pulse a le Mong | 90J |

| Maqhubu a Range | 1-20Hz |

| Pulse Width | 0.1 ~ 20ms |

| Sistimi ea Taolo | PC-CNC |

| Mokhoa oa ho shebella | Monyetla oa microscope le CCD |

| Mohloli oa Pompo | Lebone la Xenon |

| Mokhoa oa ho Pholisa | Ho Pholisa Metsi ka Ntle |

| Kakaretso ea Matla | 7KW |

| Tlhokahalo ea Matla | 220V±10% /50Hz le 60Hz e lumellana |

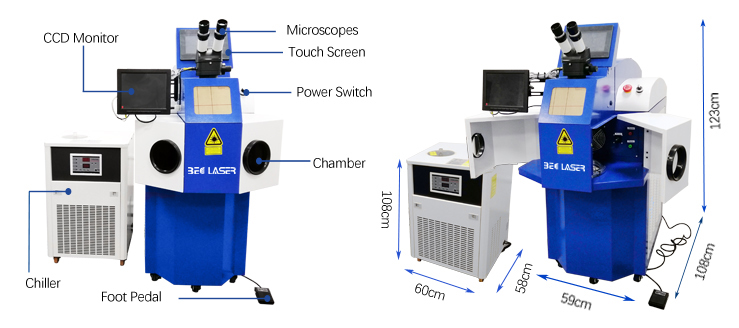

| Boholo le Boima ba Mochini | Hoo e ka bang 112 * 67 * 138cm, boima ba 'mele bo pota-potileng 153KG |

| Chiller Packing Size & Weight | Hoo e ka bang 60x58x108cm, boima ba 'mele bo ka bang 88KG |

Mehlala

Mehaho

Lintlha