3-Axis Laser Welding Machine-Mofuta oa Boiketsetso

Kenyelletso ea Sehlahisoa

Laser welding e sebelisa matla a matla a laser pulses ho futhumatsa thepa sebakeng se senyenyane.Matla a mahlaseli a laser a kenella ka har'a thepa ka ho tsamaisa mocheso, 'me thepa e qhibiliha ho etsa letamo le khethehileng le qhibilihisitsoeng.Ke mofuta o mocha oa mokhoa oa ho cheselletsa, haholo-holo bakeng sa ho cheselletsa thepa e nang le marako a masesaane le likarolo tse nepahetseng.E khona ho hlokomela li-welding, butt welding, stitch welding, welding ea ho tiisa, joalo-joalo, ka tekanyo e phahameng ea likarolo, bophara bo nyane ba weld, le sebaka se senyenyane se amehileng ke mocheso.Deformation e nyane, lebelo la welding ka potlako, seam e boreleli le e ntle ea welding, ha ho na tlhoko kapa ts'ebetso e bonolo ka mor'a ho tjheseletsa, boleng bo holimo ba seam, ha ho masoba a moea, taolo e nepahetseng, sebaka se senyenyane sa ho tsepamisa maikutlo, ho nepahala ha maemo a holimo, le ho le bonolo ho elelloa automation.

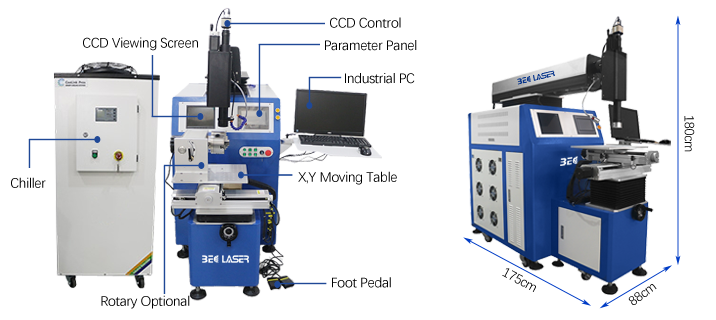

Moralo o felletseng oa lilepe tse tharo (li-axes tse 'ne li fumaneha), X, Y tabletable e ka fetoloa ka bo eona.Bophahamo ba benche ea mosebetsi le tsela ea laser le eona e ka fetoha.Software phetha tjheseletsa trace motsamao, tjheseletsa letheba, mola o otlolohileng, selikalikoe, oval le lisekoere joalo-joalo leha e le efe sefofane trace le bonolo sebaka geometry trace.Ntle ho moo, mochine ona o ka sebelisoa ho lokisa liforomo tse kholo tse boima ba lithane, ka thuso ea trundle-proof trundle le ho ikemela ka maoto a maoto, ho bonolo ho tlosa ho fasten sehlahisoa sena.

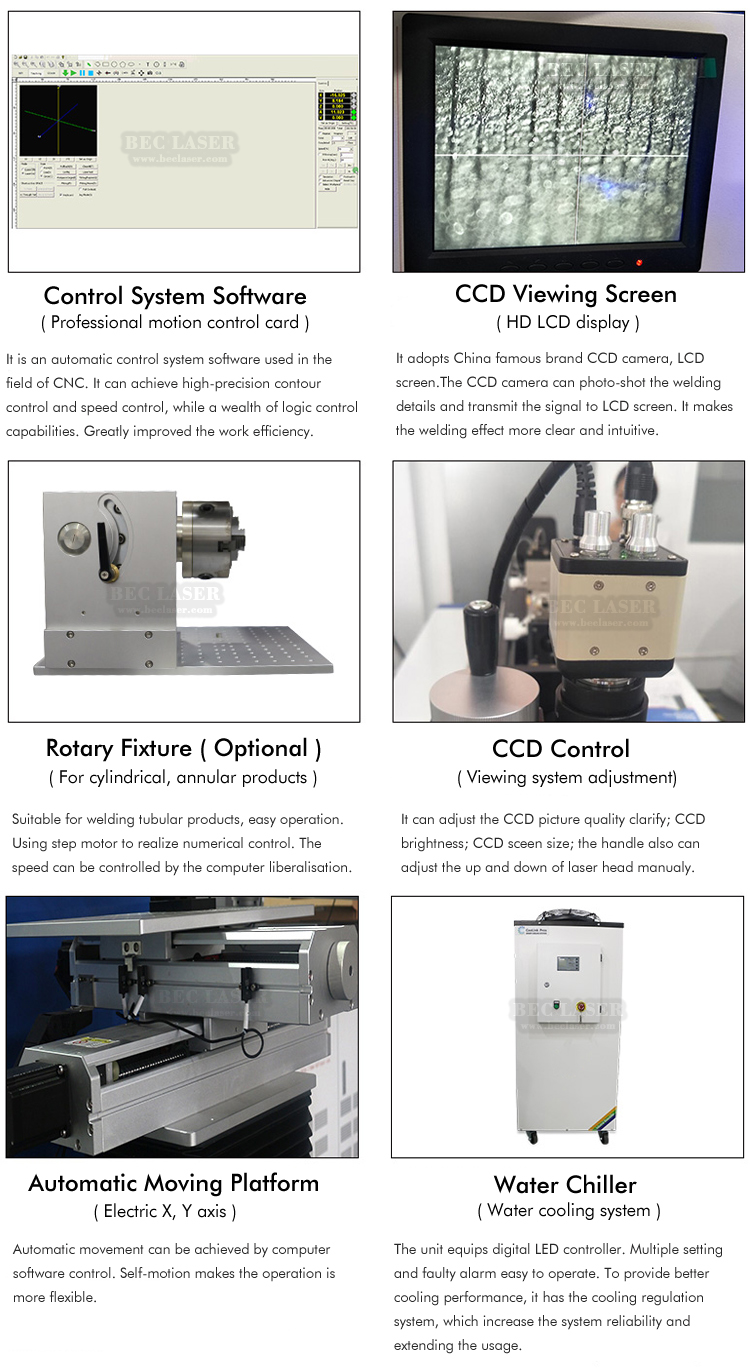

Likaroloana

1. Mohloli oa laser o sebelisa theknoloji e tsoetseng pele ea Jeremane, modular gilded cavity.E na le sebopeho sa matla a phahameng a tlhahiso, ts'ebetso e tsitsitseng le tlhokomelo e bonolo.

2. E na le software ea othomathike ea ho laola e ka fihlelang taolo e nepahetseng ea li-contour le taolo ea lebelo, ha e ntse e na le bokhoni ba ho laola logic.E ntlafalitse ts'ebetso ea ts'ebetso haholo.

3. Matla a laser a hlohlelletsoa ke di-pulse XE-lamp, e laoloang ke pulse ea kamehla, e hlophisitsoeng ke lenaneo la bohlale.

4. Letlapa la skrine la ho ama ho lokisa li-parameter, tse bonolo le tse bonolo.

5. Benche ea mosebetsi e ka phahamisoa, 'me ea sisinyeha ka litekanyo tse tharo ka ho toba.Hlooho ea laser le benche ea mosebetsi le tsona li ka phahamisetsoa holimo le tlase ka letsoho.

6. Ts'ebetso ea CCD e lumella opareitara hore a shebe mohlala oa tšebetso ka ho hlaka.

7. Sesebelisoa sa rotary se ikhethela bakeng sa ho lokisa lintho tsa cylindrical annular.

Kopo

E sebetsa ho li-welding kettles, likopi tsa vacuum, likotlolo tsa tšepe tse sa hloekang, li-sensor, tungsten, filaments, diode tsa matla a phahameng (triode), li-alloys tsa aluminium, likoekoe tsa lilaptop, libeteri tsa selefouno, mabati a mamati, li-dies, likarolo tsa lisebelisoa tsa motlakase, li-filters, li-nozzles tsa oli. , lihlahisoa tsa tšepe tse sa hloekang, lihlooho tsa lihlopha tsa golf, li-zinc alloy craftworks, joalo-joalo.

Mekhahlelo

| Mohlala | BEC-AW200 | BEC-AW300 | BEC-AW400 | BEC-AW500 |

| Matla a Laser | 200W | 300W | 400W | 500W |

| Laser Wavelength | 1064 nm | |||

| Max.Matla a Pulse a le Mong | 80J | 100J | 120J | 150J |

| Mofuta oa Laser | ND: YAG | |||

| Laser Pulse Frequency | 0.1-100Hz | |||

| Pulse Width | 0.1-20ms | |||

| Sebaka sa mosebetsi | X=350mm, Y=200mm, e fihlang ho 200KG | |||

| X, Y, Z Motsamao | X, Y Axis e tsamaea ka bo eona;mefuta e fapaneng ea 300×300mm (Ho ikhethela), Z-axis e ka phahamisoa. | |||

| Ho Shebella Sisteme | microscope le mokhoa oa ho beha leihlo setšoantšo sa CCD ho holisa | |||

| Sistimi ea Taolo | Taolo ea lenaneo la PLC kapa PC & Microcomputer | |||

| Tšebeliso ea Matla | 6KW | 10KW | 12KW | 16KW |

| Mokhoa oa ho Pholisa | Pholiso ea metsi | |||

| Tlhokahalo ea Matla | 220V±10%/380V±10% 50Hz kapa 60Hz | |||

| Pack Size & Weight | Mochine: 90 * 175 * 182cm, chiller Metsi: 87 * 80 * 182cm;Boima bo boholo bo ka bang 660KG | |||

Mehlala

Mehaho

Lintlha