Fiber Laser Welding Machine-Handheld Type

Kenyelletso ea Sehlahisoa

Mokhoa oa ho sebetsa oa mochini o ts'oarellang oa fiber laser o ts'oaretsoeng ka letsoho, oa ho ts'oara ka letsoho oa tenyetseha ebile o bonolo, 'me sebaka sa ho tjheseletsa se telele.Ho sebelisa sethunya sa ho tjheseletsa ka letsoho ho nka sebaka sa tsela e fetileng e sa fetoheng ea lebone ho na le melemo ea ts'ebetso e bonolo, li-welding seams tse ntle, lebelo la welding ka potlako mme ha ho na lisebelisoa.

Bakeng sa ho tjheseletsa lipoleiti tse tšesaane tse se nang tšepe, lipoleiti tsa tšepe, lipoleiti tse nang le masenke le lisebelisoa tse ling tsa tšepe, li ka nkela sebaka sa setso sa arc arc welding, welding ea motlakase le lits'ebetso tse ling.Mochini o ts'oaretsoeng ka letsoho oa faeba laser tjheseletsa o sebelisoa haholo bakeng sa welding ea laser ea sebaka se selelele le li-workpieces tse kholo.Sebaka se amehileng ke mocheso se senyenyane nakong ea welding, 'me se ke ke sa baka deformation ea mosebetsi, blackening, le mesaletsa ka morao.Botebo ba ho tjheseletsa bo boholo, ho tjheseletsa ho tiile, mme ho qhibidiha ho lekane.Ha ho na lekhalo karolong e kholo ea thepa e qhibilihisitsoeng ka har'a letamo la ho qhibiliha le substrate.

Mochini oa welding oa Handheld Fiber laser welding ke sesebelisoa sa welding sa laser se kopanyang mahlaseli a laser a matla ka har'a fiber ea optical, kamora phetisetso ea sebaka se selelele, ebe e fetoloa mabone a tšoanang ka seiponeng se kopantseng ho shebana le karolo ea mosebetsi ho kenya ts'ebetsong tjheseletsa.Mekhoa ea ho tjheseletsa e kenyelletsa welding e otlolohileng, welding ea paraller, stitch welding joalo-joalo.

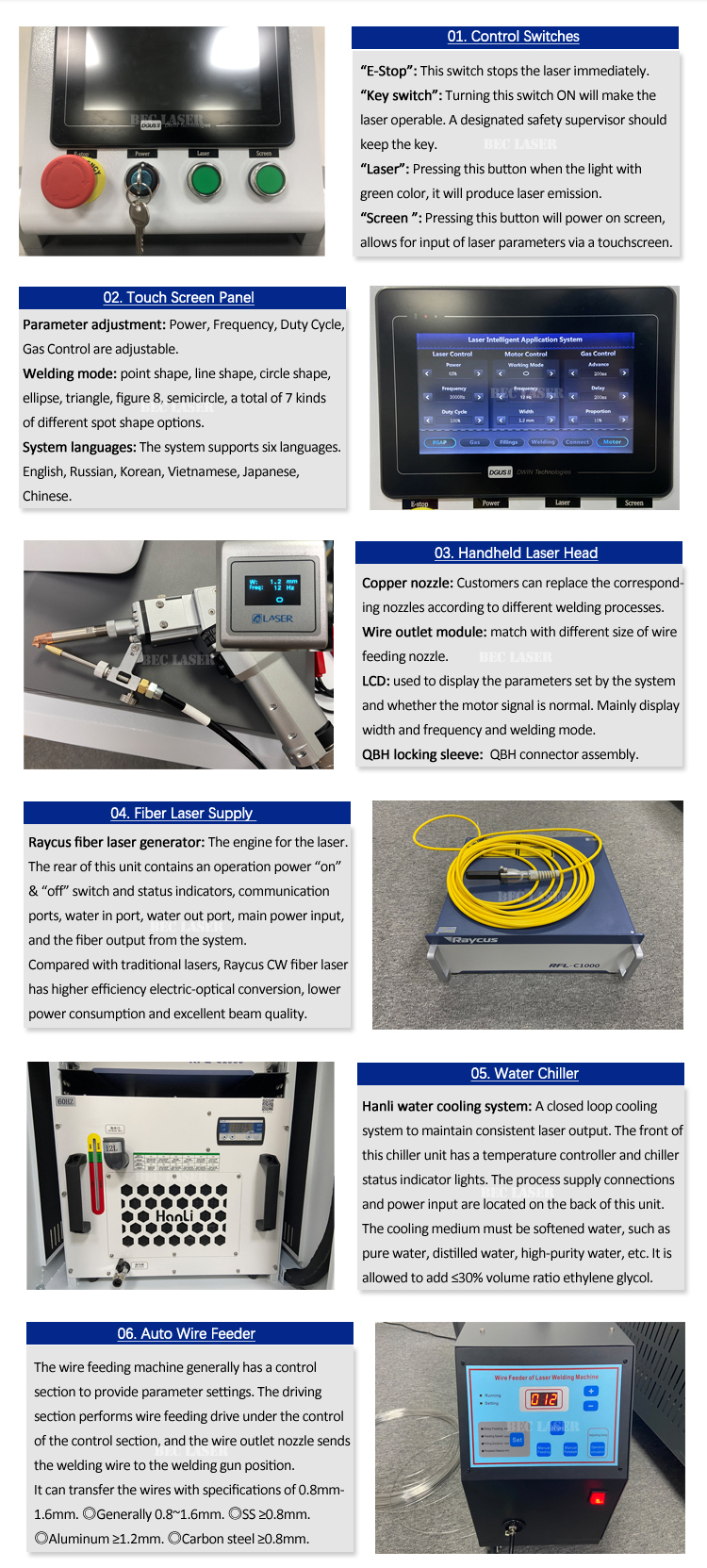

Likaroloana

1. Fast tjheseletsa lebelo, 2 ~ 10 makhetlo a ka potlako ho feta setso tjheseletsa.

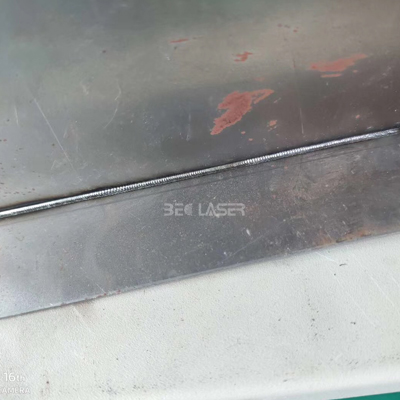

2. Sekhahla sa weld se tšesaane, botebo ba ho kenella bo boholo, taper e nyane, e nepahetseng e phahame, ponahalo e boreleli, e bataletse ebile e ntle.

3. Palo ea deformation ea mocheso e nyenyane, 'me sebaka se qhibilihisang le sebaka se amehileng ke mocheso se moqotetsane ebile se tebile.

4. Sekhahla se phahameng sa ho pholisa, se ka etsang weld sebopeho se setle sa weld le ts'ebetso e ntle ea manonyeletso.

5. Laser welding e na le lisebelisoa tse fokolang le bophelo bo bolelele ba tšebeletso.

6. Ho sebetsa ha bonolo ha ho hloke koetliso, e se nang botsoalle haholoanyane.

Kopo

Laser tjheseletsa e ka sebelisoa ho tjheseletsa tšepe e sa hloekang, aluminium, koporo, chromium, nickel, titanium le litšepe tse ling kapa alloys, e ka boela sebelisoa bakeng sa mefuta e fapaneng ya tjheseletsa pakeng tsa thepa e fapaneng, tse kang: koporo - koporo, titanium - khauta, Titanium. - molybdenum, nickel - koporo joalo-joalo.

Mekhahlelo

| Mohlala | HW1000 | HW1500 | HW2000 |

| Matla a Laser | 1000W | 1500W | 2000W |

| Laser Wavelength | 1080±5 nm | ||

| Mohloli oa Laser | Raycus (mohloli oa laser oa MAX/JPT ka boikhethelo) | ||

| Mokhoa oa ts'ebetso | Tsoelang pele | ||

| Mokhoa oa ho tsoa | QBH e tloaelehileng | ||

| Sistimi ea Welding | Hlooho ea ho tjheseletsa e tjheseletsang ka letsoho ya QILIN | ||

| Mofani oa Mohala | Auto wire feeder | ||

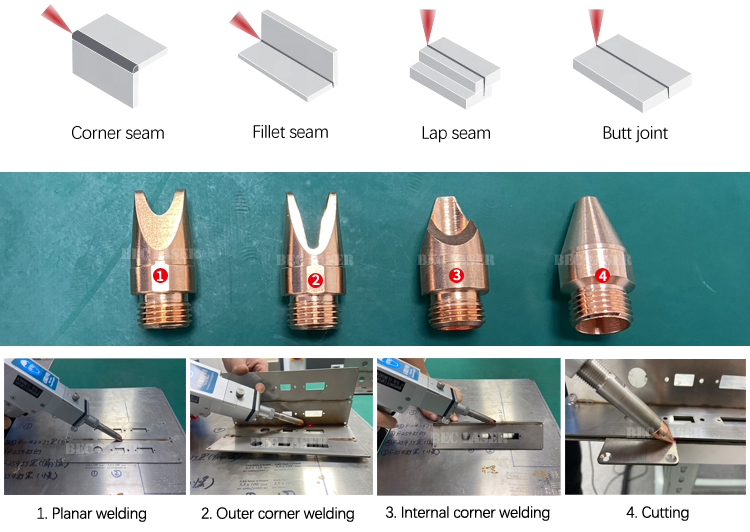

| Nozzle ea Welding | Planar, sekhutlo se ka ntle, sekhutlo se ka hare, nozzle e sehang | ||

| Modulation Frequency | 50 ~ 50,000Hz | 50 ~ 20,000Hz | 1 ~ 5,000Hz |

| Boleng ba Beam | M2: 1.3 (25μm) | M2: 5-6 (50μm) | M2: 5-7 (50μm) |

| Red Guide Laser Matla | 0.1 ~ 1 mW | 0.1 ~ 1 mW | 0.5 ~ 1 mW |

| Tšireletso ea Khase | Naetrojene kapa Argon | ||

| Mokhoa oa ho Pholisa | Sistimi ea ho futhumatsa metsi | ||

| Mocheso oa Mosebetsi | 0 °C - 35 °C ( Ha ho condensation) | ||

| Kakaretso ea Matla | ≤6KW | ≤7KW | ≤9KW |

| Tlhokahalo ea Matla | 220V±10% 50Hz kapa 60Hz | 220V±10% 50Hz kapa 60Hz | 380V±10% 50Hz kapa 60Hz |

| Pack Size & Weight | Mochine: Ho pota 127 * 73 * 129cm, 198KG; Wire Feeder: Ho pota 69 * 59 * 64cm, 48KG. | ||

Mehlala

Mehaho

Lintlha