Cantilever Laser Welding Machine-Ka Letsoho le Botsoa

Kenyelletso ea Sehlahisoa

Mochini oa ho cheselletsa hlobo oa laser e boetse ke lekala la mochini oa welding oa laser.Molao-motheo oa ho sebetsa ke ho sebelisa matla a matla a laser pulses ho futhumatsa thepa sebakeng se senyenyane.Matla a mahlaseli a laser a aroloa ka har'a thepa ka ho tsamaisa mocheso, 'me thepa e qhibiliha ho etsa letamo le khethehileng la Molten.

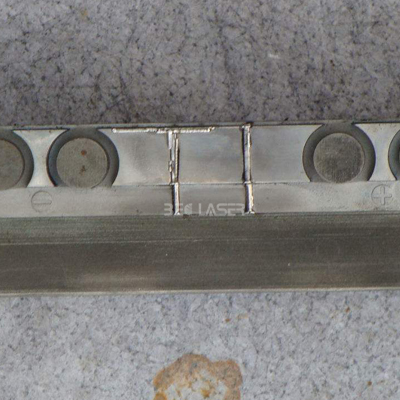

Ke mofuta o mocha oa mokhoa oa ho cheselletsa, haholo-holo bakeng sa ho cheselletsa thepa e nang le marako a masesaane le likarolo tse nepahetseng.E khona ho hlokomela li-welding, butt welding, stitch welding, welding ea ho tiisa, joalo-joalo, ka tekanyo e phahameng ea likarolo, bophara bo nyane ba weld, le sebaka se senyenyane se amehileng ke mocheso.Deformation e nyane, lebelo la welding ka potlako, seam e boreleli le e ntle ea welding, ha ho na tlhoko kapa ts'ebetso e bonolo ka mor'a ho tjheseletsa, boleng bo holimo ba seam, ha ho masoba a moea, taolo e nepahetseng, sebaka se senyenyane sa ho tsepamisa maikutlo, ho nepahala ha maemo a holimo, le ho le bonolo ho elelloa automation.Mechini e nang le matla a phahameng ea laser e kentsoe, e ka hlokomelang mefuta e fapaneng ea mochini oa welding oa laser le tokiso ea lisebelisoa tse teteaneng.

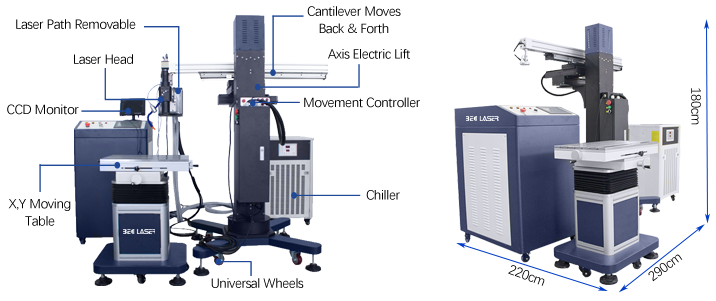

Letsoho la cantilever le ka fetoleloa ka mahlakoreng 'ohle le li-angles.Esita le hlobo e ke ke ea sisinyeha, letsoho la cantilever le ka tsamaea ka bolokolohi, le rarolla bothata haholo, le ntlafatsa katleho ea ho sebetsa.Mochini o ka tjheseletsa sebaka se moqotetsane, welding e tebileng ea ho lokisa cavity, e ke ke ea utloisa lerako le potolohileng bohloko.E ke ke ea senya sehlahisoa sa hlobo kapa sa teba ho pota-pota letamo la weld.

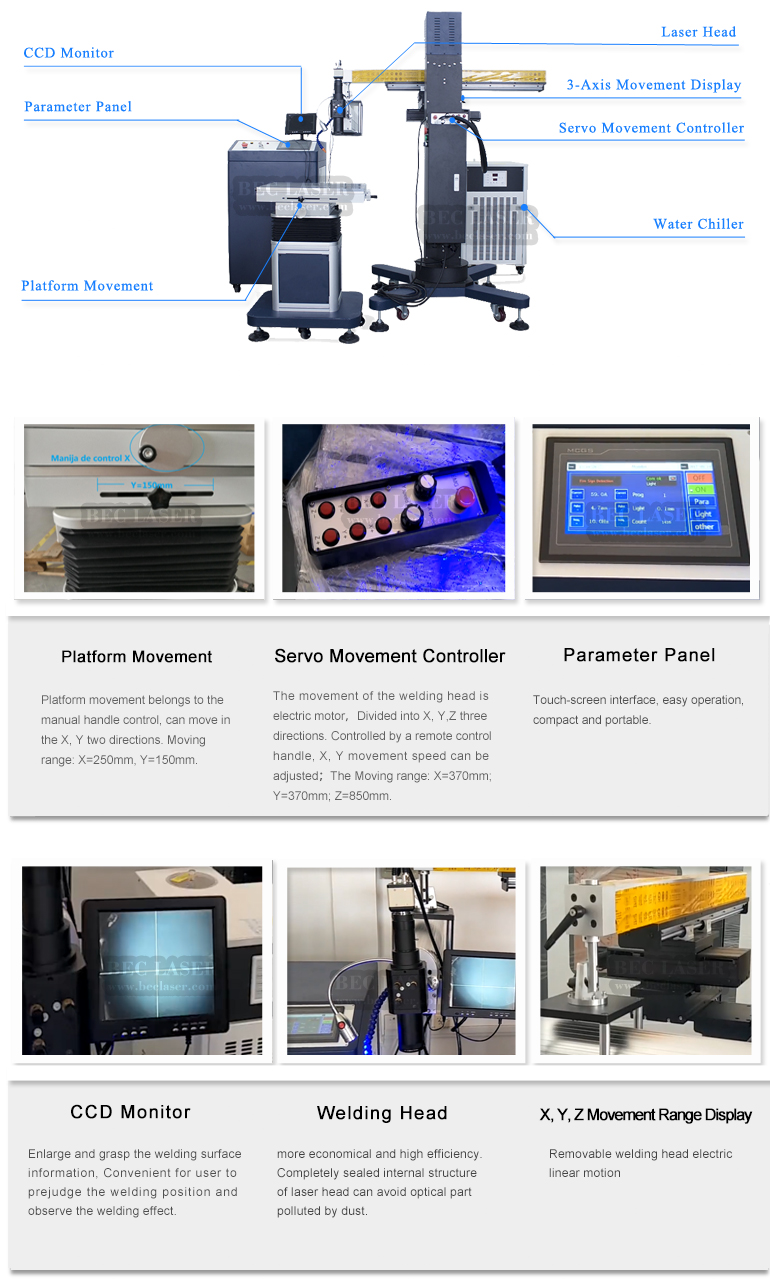

Likaroloana

1. Mohloli oa laser o sebelisa theknoloji e tsoetseng pele ea Jeremane, modular gilded cavity.E na le sebopeho sa matla a phahameng a tlhahiso, ts'ebetso e tsitsitseng le tlhokomelo e bonolo.

2. Letlapa la skrine la ho ama ho lokisa li-parameter, tse bonolo le tse bonolo.

3. Benche ea mosebetsi X, Y motsamao o sebelisa sekoti se nepahetseng sa bolo le leseli le phahameng le otlolohileng la tataiso ea seporo le ho tenyetseha, boemo bo nepahetseng, bo fihlang ho 200 kg;

4. Hlooho ea laser e ka thellela pele le morao, ho phahamisa letsoho, hlooho ea laser e ka fetoloa habonolo likhato tse 180, ho bonolo ho lokisa welding ka lehlakoreng le leng;

5. E na le taolo e hole, phetoho e tenyetsehang ea boemo ba 360 degree angle ea welding.Ha u sheba hlobo e kholo, u se ke ua hloka benche ea mosebetsi, ka ho toba fatše kapa forklift hlobo tjheseletsa.

Kopo

E ne e sebelisetsoa ho lokisa liforomo tse kholo/ho bopa bocha.Lisebelisoa tse ka chesetsoang li ngata: tšepe ea motsoako o batang, tšepe ea motsoako o chesang, tšepe ea tšepe ea nickel, alloy ea tšepe, alloy e phahameng ea aluminium, joalo-joalo.

Mekhahlelo

| Mohlala | BEC-MW200C | BEC-MW300C | BEC-MW400C | BEC-MW500C |

| Matla a Laser | 200W | 300W | 400W | 500W |

| Laser Wavelength | 1064 nm | |||

| Max.Matla a Pulse a le Mong | 80J | 100J | 120J | 150J |

| Mofuta oa Laser | ND: YAG | |||

| Laser Pulse Frequency | 0.1-100Hz | |||

| Pulse Width | 0.1-20ms | |||

| Sebaka sa mosebetsi | Sebaka se tsamaeang sa sethala: X=250mm, Y=150mm, se fihlang ho 200KG | |||

| Motsamao oa Cantilever | X=370mm, Y=370mm, Z=850mm | |||

| Ho Shebella Sisteme | Ka boikhethelo, microscope kapa CCD monitor | |||

| Sistimi ea Taolo | Taolo ea lenaneo la Microcomputer | |||

| Tšebeliso ea Matla | 6KW | 10KW | 12KW | 16KW |

| Mokhoa oa ho Pholisa | Pholiso ea metsi | |||

| Tlhokahalo ea Matla | 220V±10%/380V±10% 50Hz kapa 60Hz | |||

| Pack Size & Weight | Mochine: 295x105x195cm, chiller ea metsi: 60x58x108cm;Boima bo boholo bo ka bang 510KG | |||

Mehlala

Mehaho

Lintlha