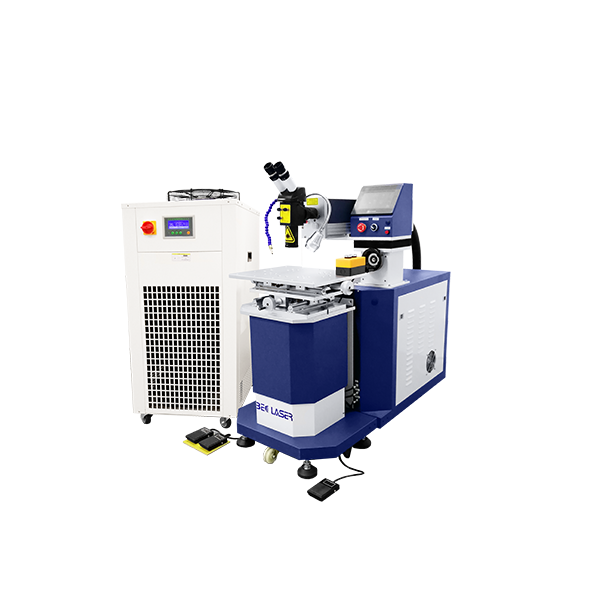

Mold Laser Welding Machine-Mofuta oa Manual

Kenyelletso ea Sehlahisoa

Mabenkele a kajeno a ho sebetsa ka mokhoa o nepahetseng oa ho cheselletsa litšepe tse sebetsanang le hlobo ea ente ea polasetiki, li-dies and tooling li na le mefuta e mengata ea mahlale a macha a fumanehang ho ntlafatsa bokhoni ba bona ba ho fana ka boleng bo holimo, boqapi le ts'ebeletso ho bareki ba bona.E 'ngoe ea mahlale a ntseng a hola ka potlako ke ts'ebeliso ea mochini oa welding oa laser e le mokhoa o mong ho fapana le oa setso oa GTA oa microscope.

E 'ngoe ea lintlha tsa bohlokoa mabapi le ho etsa "laser welding" ea letsoho e sebetsang molemong oa tlhahiso le tokiso ea Tool and Die kapa Mold e ne e le nts'etsopele ea mohopolo oa "free-moving".Ka mokhoa ona, laser e hlahisa molumo oa ho otla ha leseli o emeng o lebisitsoe ka har'a moriri o pharalletseng oa microscope.Laser pulse e ka laoloa ka boholo le matla.

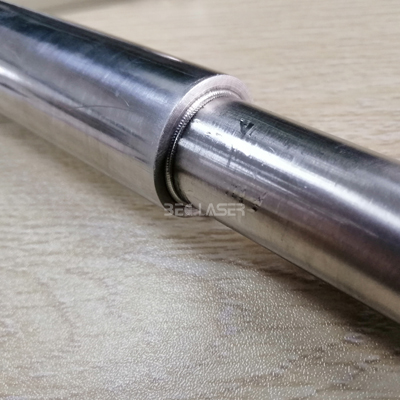

Laser tjheseletsa e loketse bakeng sa diphetolo le tokiso holim'a hlobo, lisebelisoa le ho shoa ebang ke ka lebaka la tšenyo, ho senyeha le ho taboha, kapa phetoho ea moralo oa workpiece.Ts'ebetso e potlakile, e nepahetse ebile e ke ke ea senya libaka tse potolohileng.

Moralo o thehiloeng ho batho ho latela ergonomics o etsa hore mochini o nepahale, o shebahale hantle, o sebetse hantle, 'me bophelo bo bolelele, o loketse ho lokisoa ha hlobo ka nepo.Ke theknoloji e nepahetseng ea ho tjheseletsa e nang le matla a phahameng a mocheso a phahameng a laser, e sebetsang hantle ho cheselletsa le ho lokisa likaroloana tse ling tse senyehileng tsa hlobo, joalo ka: mapetsong, maqhubu, ho phatloha, ho benya ha hlobo, mats'oao a tiiso, joalo-joalo. hlobo.E ntlafatsoa ka ho hlahisoa ha theknoloji e tsoetseng pele ea Jeremane.

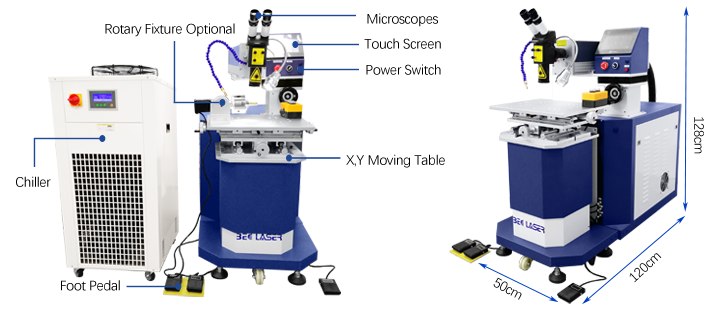

Likaroloana

1. Ceramic converging cavity ha e na kutu le mocheso o phahameng, 'me e na le bophelo ba tšebeletso ea lilemo tse 8-10.Bophelo ba lebone la xenon bo feta makhetlo a limilione tse 8.

2. Ho sebelisa mokhoa o tsoetseng pele ka ho fetisisa oa ho sireletsa leseli ho felisa ho halefisoa ke mahlo ka leseli nakong ea ho sebetsa.

3. Tšoara skrineng phanele ho lokisa liparamente, e leng bonolo le e loketseng.

4. Benche ea mosebetsi e ka phahamisoa, 'me ea sisinyeha ka litekanyo tse tharo.

5. Boholo ba sebaka se khanyang bo ka fetoloa.

6. Sesebelisoa sa rotary se ikhethela bakeng sa ho lokisa lintho tsa cylindrical annular.

Kopo

E loketse ho bopa ka mokhoa o nepahetseng oa ente, ho lahla, ho lokisa hlobo le liindasteri tse ling;mefuta eohle ea tšepe ea motsoako o batang, tšepe e phahameng ea alloy forging, ho kenyelletsa le tšepe ea tšepe ea tšepe ea Nickel, tšepe ea boemo bo holimo, li-alloys tsa koporo, koporo ea beryllium, aluminium e thata haholo le lisebelisoa tse ling tsa tšepe.

Mekhahlelo

| Mohlala | BEC-MW200 | BEC-MW300 | BEC-MW400 |

| Matla a Laser | 200W | 300W | 400W |

| Laser Wavelength | 1064 nm | ||

| Max.Matla a Pulse a le Mong | 80J | 100J | 120J |

| Mofuta oa Laser | ND: YAG | ||

| Laser Pulse Frequency | 0.1-100Hz | ||

| Pulse Width | 0.1-20ms | ||

| Botebo ba Welding | 0.1-1.5 limilimithara | 0.1-2 limilimithara | 0.1-3 limilimithara |

| Sebaka sa mosebetsi | X=450mm, Y=350mm (X,Y e ka fetoloa ka letsoho, Z-axis e ka phahamisoa) | ||

| Ho Shebella Sisteme | Microscope (setšoantšo sa CCD sa ho holisa) | ||

| Sistimi ea Taolo | Taolo ea lenaneo la Microcomputer | ||

| Tšebeliso ea Matla | 6KW | 10KW | 12KW |

| Mokhoa oa ho Pholisa | Pholiso ea metsi | ||

| Tlhokahalo ea Matla | 220V±10%/380V±10% 50Hz kapa 60Hz | ||

| Pack Size & Weight | Machine: 144 * 66 * 127cm, Metsi chiller: 87 * 65 * 146cm;Boima bo boholo bo ka bang 450KG | ||

Mehlala

Mehaho

Lintlha