Mochini oa tjheseletsa oa laserke mofuta oa lisebelisoa tsa ho tjheseletsa tse sebelisoang haholo tlhahiso ea indasteri, hape ke mochini oa bohlokoahali bakeng sa ts'ebetso ea lisebelisoa tsa laser.Mechini ea welding ea laser e se e hōlile butle-butle ho tloha tsoelo-pele ea pele ho fihlela joale, 'me mefuta e mengata ea mechine ea ho tjheseletsa e nkiloe.

Laser welding ke mofuta o mocha oa mokhoa oa ho tjheseletsa le e 'ngoe ea likarolo tsa bohlokoa tsa ts'ebeliso ea theknoloji ea ho lokisa thepa.Laser tjheseletsa e haholo-holo ikemiseditse ho tjheseletsa thepa tšesaane e marako le likarolo ho nepahala.Ts'ebetso ea tjheseletsa ke ea mofuta oa conduction ea mocheso, ke hore, bokaholimo ba sebaka sa mosebetsi bo futhumatsoa ke mahlaseli a laser, 'me mocheso o holim'a metsi o feta The conduction ea mocheso e fapana ho ea ka hare,' me workpiece e qhibiliha ho theha letamo le khethehileng le entsoeng ka ho qhibiliha. ho laola litekanyo tse kang bophara, matla, matla a tlhōrō le maqhubu a ho pheta-pheta a laser pulse.E khona ho hlokomela ho tjheseletsa ha letheba, ho tjheseletsa butt, stitch welding, welding welding, jj. Bophara ba seam sa welding bo nyane, sebaka se amehileng ke mocheso se nyane, deformation e nyane, lebelo la welding le potlakile, seam sa welding se boreleli ebile se setle; 'me ha ho phekolo kapa phekolo e bonolo e hlokahalang ka mor'a ho cheselletsa.Seam sa ho cheselletsa ke sa boleng bo holimo, ha se na li-pores, se ka laoloa ka nepo, se na le sebaka se senyenyane sa ho tsepamisa maikutlo, 'me se na le ho nepahala ha boemo bo holimo,' me ho bonolo ho iketsetsa sona.

Tlhokomelo ea mochini oa welding oa laser:

Themochine oa ho tjheseletsa lasere hloka tlhokomelo, 'me mocheso oa tanka ea metsi o hloka ho fetoloa mariha le lehlabula.Thibela mocheso oa kamore hore o se ke oa bata haholo kapa o chesa haholo ho ama matla a tlhahiso ea laser.Ho kgothaletswa ho fetola mocheso oa tanka ea metsi ho likhato tse 3 ~ 5 ho feta mocheso oa kamore ho ea ka mocheso oa kamore, o ke keng oa netefatsa feela matla a hlahisoang ke laser, empa hape o netefatsa botsitso ba tlhahiso ea laser.

1. Boemo ba mocheso oa metsi

Mocheso oa metsi a pholileng o na le tšusumetso e tobileng ho katleho ea phetoho ea electro-optical, botsitso le condensation.Tlas'a maemo a tloaelehileng, mocheso oa metsi a pholileng o behiloe ka tsela e latelang: metsi a hloekileng (a boetse a bitsoa metsi a mocheso o tlaase, a sebelisetsoang ho pholisa mochine oa mochini oa welding oa laser), mocheso oa metsi oa potoloho ea metsi o lokela ho behoa hoo e ka bang 21 ° C. mme e ka bewa ka nepo pakeng tsa 20 le 25 °C ho ya ka maemo.Phetoho.Phetoho ena e hloka ho etsoa ke setsebi.

Thempereichara ea metsi ea metsi a senyehileng a DI (a tsejoang hape e le metsi a mocheso o phahameng, a sebelisetsoang ho pholisa likarolo tsa optical) a lokela ho behoa lipakeng tsa 27°C le 33°C.Mocheso ona o lokela ho fetoloa ho latela mocheso le mongobo o teng.Ha mongobo o phahame, mocheso oa metsi oa metsi a DI o lokela ho eketseha ka tsela e nepahetseng.Molao-motheo oa mantlha ke: mocheso oa metsi oa DI o lokela ho ba ka holim'a ntlha ea phoka.

2. Mehato ea thibelo e kang likarolo tsa ka hare tsa elektronike kapa tsa optical

Sepheo se seholo ke ho thibela condensation ea likarolo tsa elektronike kapa optical ka hare homochine oa ho tjheseletsa laser.Etsa bonnete ba hore chassis ha e na moea: hore na mamati a khabinete a teng 'me a koetsoe ka thata;hore na liboutu tse holimo li tiisitsoe;hore na sekoahelo se sireletsang sa sebopeho sa taolo ea puisano se sa sebelisoeng ka morao ho chassis se koahetsoe, le hore na tse sebelisoang li tsitsitse.Boloka mochine oa welding oa laser o ntse o le teng 'me u ele hloko tatellano ea ho tima le ho tima.Kenya kamore e nang le moea o pholileng bakeng sa mochini oa welding oa laser, kenya ts'ebetso ea "air-conditioning dehumidification" 'me u boloke moea oa moea o ntse o sebetsa ka mokhoa o tsitsitseng le o tsitsitseng (ho kenyeletsoa bosiu), e le hore mocheso le mongobo ka phapusing e nang le moea o pholileng li bolokoe. 27°C le 50% ka ho latellana.

3. Sheba likarolo tsa tsela ea optical

E le ho etsa bonnete ba hore laser esale e le maemong a tloaelehileng a ho sebetsa, kamora ts'ebetso e tsoelang pele kapa ha e emisoa ka nako e itseng, likarolo tse tseleng ea optical joalo ka molamu oa YAG, diaphragm ea dielectric le khalase e sireletsang ea lense. e lokela ho hlahlojoa pele e qala ho etsa bonnete ba hore likarolo tsa optical ha lia silafala., Haeba ho na le tšilafalo, e lokela ho sebetsanoa ka nako ho netefatsa hore karolo e 'ngoe le e' ngoe ea optical e ke ke ea senyeha tlas'a mahlaseli a matla a laser.

4. Hlahloba le ho lokisa laser resonator

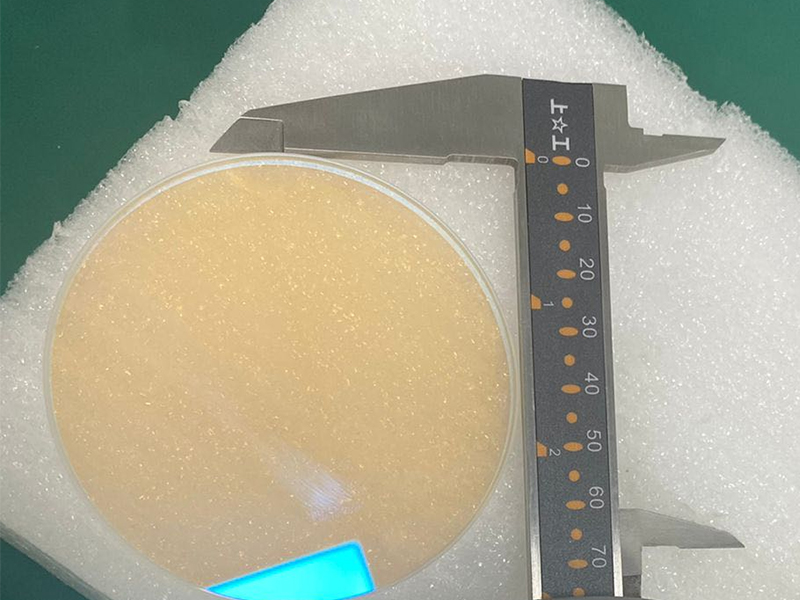

Basebelisi ba mochini oa welding oa laser hangata ba ka sebelisa pampiri e ntšo ea setšoantšo ho lekola sebaka sa tlhahiso ea laser.Hang ha sebaka se sa lekaneng kapa lerotholi la matla le fumanoa, resonator ea laser e lokela ho lokisoa ka nako ho netefatsa boleng ba mahlaseli a tlhahiso ea laser.Basebelisi ba ho lokisa liphoso ba tlameha ho ba le kutloisiso e tloaelehileng ea ts'ireletso ea laser, 'me ba roale likhalase tse khethehileng tsa laser nakong ea mosebetsi.Phetoho ea laser e tlameha ho etsoa ke basebetsi ba koetlisitsoeng ka ho khetheha, ho seng joalo likarolo tse ling tse tseleng ea optical li tla senyeha ka lebaka la phetoho e fosahetseng kapa polarization ea laser.

5. Ho hloekisa mochine oa tjheseletsa oa laser

Pele le ka mor'a mosebetsi o mong le o mong, qala ka ho hloekisa tikoloho ho etsa hore fatše ho ome le ho hloeka.Ebe u etsa mosebetsi o motle oa ho hloekisa lisebelisoa tsa mochini oa welding oa laser oa YAG, ho kenyeletsoa bokantle ba chassis, sistimi ea ho shebella le sebaka sa mosebetsi, se lokelang ho se be le litšila le ho hloeka.Lilense tse sireletsang li lokela ho bolokoa li hloekile.

Mechini ea tjheseletsa ea laserli sebelisoa haholo ha ho sebetsoa meno a meno, ho tjheseletsa mabenyane, ho tjheseletsa letlapa la silicon, welding sensor, welding cap, betri cap tjhesella le hlobo.

Nako ea poso: May-06-2023