Hajoale,mechine ea laser tjheseletsali 'nile tsa sebelisoa haholo mokhabisong oa papatso, mabenyane, mamati le lifensetere le liindasteri tse ling.Phapang ke efe lipakeng tsa welding ea laser le welding ea argon arc, soldering le theknoloji e meng ea khale ea welding?E etsa engmochine oa ho tjheseletsa laserho itšetleha ka hore butle-butle e be eona e ka sehloohong ea theknoloji ea tjheseletsa ea hona joale?

Mochini oa tjheseletsa oa laserke mofuta o mocha oa mokhoa oa ho tjheseletsa, haholo-holo bakeng sa ho tjheseletsa ha thepa e tshesaane e nang le marako le likarolo tse ntle, tse ka qetang ho tjheseletsa letheba, ho tjheseletsa butt, ho tjheseletsa ho tjheseletsa, ho tiisa ho tjheseletsa, joalo-joalo. seam e ntle ea welding, ha ho na tlhoko kapa kalafo e bonolo feela kamora ho tjheseletsa, boleng bo holimo ba seam, ha ho na li-pores, taolo e nepahetseng, letheba le lenyenyane la leseli, ho nepahala ha boemo bo phahameng, ho bonolo ho e tlatsa.E sebelisa matla a matla a laser pulses ho futhumatsa thepa ka mokhoa o itseng sebakeng se senyenyane.Matla a mahlaseli a laser a kenella ka har'a thepa ka ho tsamaisa mocheso, a qhibilihisa thepa ho etsa letamo le khethehileng le qhibilihisitsoeng, ebe e qhala lisebelisoa tse peli tse kopane hammoho.

Mokhoa oa ho cheselletsa laser o sebetsa joang

Ho tjheseletsa ka laser ke ho irradiate lebone la laser le matla a phahameng ho ea holim'a tšepe, 'me ka ho sebelisana pakeng tsa laser le tšepe, tšepe e qhibiliha ho etsa weld.Ho qhibiliha ha tšepe ke e 'ngoe feela ea liketsahalo tsa' mele nakong ea ho sebelisana ha laser le tšepe.Ka linako tse ling matla a khanyang ha a fetohe haholo-holo ka ho qhibiliha ha tšepe, empa a bonahala ka mefuta e meng, e kang vaporization, plasma sebopeho, joalo-joalo Leha ho le joalo, ho finyella welding e ntle ea fusion, ho qhibiliha ha tšepe e lokela ho ba mokhoa o ka sehloohong oa ho fetola matla.Ho fihlela sena, hoa hlokahala ho utloisisa liketsahalo tse fapaneng tsa 'mele tse hlahisoang ke tšebelisano lipakeng tsa laser le tšepe le kamano lipakeng tsa liketsahalo tsena tsa' mele le li-parameter tsa laser, e le hore boholo ba matla a laser a ka laoloa ka ho laola likhakanyo tsa laser.

E fetoloa matla a ho qhibiliha ha tšepe ho fihlela sepheo sa ho cheselletsa.

Mekhoa ea ts'ebetso ea laser welding

1.Matla a mangata

Matla a matla ke e 'ngoe ea likarolo tsa bohlokoahali ts'ebetsong ea laser.Ka matla a matla a phahameng, lera le ka holimo le ka futhumatsoa ho isa sebakeng se belang ka nako ea microsecond, e leng se bakang mouoane o mongata.Ka hona, matla a matla a phahameng a molemo bakeng sa mekhoa ea ho tlosa thepa e kang ho phunya, ho itšeha le ho betla.Ho fokotsa matla a matla, ho nka millisecond tse 'maloa hore mocheso o ka holimo o fihle moo ho belang.Pele bokaholimo bo fetoha mouoane, lera le ka tlase le fihla sebakeng se qhibilihang, seo ho leng bonolo ho theha motsoako o motle oa fusion weld.Ka hona, ho conduction laser welding, matla a matla a sebakeng sa 104 ~ 106W / cm2.

2.Laser pulse waveform

Laser pulse shape ke taba ea bohlokoa ho welding ea laser, haholo-holo bakeng sa ho cheselletsa lakane e tšesaane.Ha lebone la laser le matla a phahameng le otla holim'a thepa, 60 ~ 98% ea matla a laser e tla bonahala le ho lahleheloa holim'a tšepe, 'me ponahalo e fapana le mocheso oa holim'a metsi.Nakong ea ts'ebetso ea laser pulse, reflectivity ea tšepe e fapana haholo.

3.Laser pulse bophara

Pulse width ke e 'ngoe ea likarolo tsa bohlokoa tsa pulse laser welding.Hase feela parameter ea bohlokoa e fapaneng le ho tlosoa ha thepa le ho qhibiliha ha thepa, empa hape ke parameter ea bohlokoa e khethollang litšenyehelo le boholo ba lisebelisoa tsa ho sebetsa.

4. Tšusumetso ea palo ea defocus ho boleng ba welding

Ho tjheseletsa ka laser hangata ho hloka mokgwa o itseng wa ho theola maikutlo, hobane boima ba matla bo bohareng ba letheba moo ho tsepamisitsweng ka laser bo phahame haholo, mme ho bonolo ho fetoha mouwane ka sekoting.Kabo ea matla a matla a batla a tšoana ho pholletsa le lifofane hole le laser focus.

Ho na le mekhoa e 'meli ea ho tlosa maikutlo: ho fokotsa maikutlo ho nepahetseng le ho fokotsa maikutlo a fosahetseng.Sefofane se tsepamisitsoeng ka holimo ho workpiece ke positive defocus, ho seng joalo ke negative defocus.Ho ea ka khopolo ea geometrical optics, ha defocus e le ntle, matla a matla a sefofane se tsamaisanang a batla a lekana, empa sebopeho sa letamo le entsoeng ka ho qhibilihisoa se fumanoeng se hlile se fapane.Ha defocus e le mpe, botebo bo boholoanyane ba ho kenella bo ka fumanoa, bo amanang le mokhoa oa ho thehoa ha letamo le qhibilihisitsoeng.Liteko li bonts'a hore ha laser e futhumetse bakeng sa 50 ~ 200us, thepa e qala ho qhibiliha, e etsa karolo ea mokelikeli ea tšepe le mouoane, e etsa mouoane oa khatello ea 'maraka, o ntšoang ka lebelo le phahameng haholo, o ntša leseli le lesoeu le khanyang.Ka nako e ts'oanang, mocheso o phahameng oa mouoane o isa tšepe e metsi moeling oa letamo le qhibilihisitsoeng, ho etsa ho tepella maikutlo bohareng ba letamo le qhibilihisitsoeng.Ha defocus e le mpe, matla a ka hare a matla a thepa a phahame ho feta a holim'a metsi, 'me ho bonolo ho theha ho qhibiliha ho matla le ho fofa, e le hore matla a leseli a ka fetisoa ka ho teba ka har'a thepa.Ka hona, lits'ebetsong tse sebetsang, ha botebo ba ho kenella bo hlokeha hore bo be boholo, ho sebelisoa ho fokotsa maikutlo a fosahetseng;ha ho tjheseletsa lisebelisoa tse tšesaane, ho lokela ho sebelisoa defocusing e ntle.

Ha ho bapisoa le theknoloji ea khale ea welding,mochine oa ho tjheseletsa lasere na le melemo e latelang

1. E na le mesebetsi e fapaneng e felletseng, 'me seam sa welding se nyane, se ka hlokomelang ho tjheseletsa ho nepahetseng;

2. Moralo oa sebopeho o bonolo ho mosebedisi, hlooho ea laser e ka otlolloa ka morao le pele, ka ho le letšehali le ka ho le letona, holimo le tlase ka letsoho, e loketseng bakeng sa ho se kopane le ho tjheseletsa sebaka se selelele sa lihlahisoa tse sa tšoaneng;

3. Sekhahla sa tjheseletsa se boreleli, sebopeho sa welding se tšoana, ha se na li-pores, ha se na tšilafalo, 'me ho na le liphoso tse fokolang tse kenyelletsoeng;

4. Lebelo la welding le potlakile, karolo ea likarolo e kholo, deformation e nyenyane, 'me ts'ebetso e tsitsitse, e ka hlokomelang tlhahiso ea boima bo itekanetseng;

4.Ke mofuta o mocha oa mokhoa oa ho cheselletsa.Laser tjheseletsa e haholo-holo ikemiseditse ho tjheseletsa thepa tšesaane e marako le likarolo ho nepahala.E ka hlokomela tjheseletsa letheba, butt welding, stitch welding, sealing welding, joalo-joalo Sebaka se senyenyane se amehileng, deformation e nyane, lebelo la tjheseletsa, seam e boreleli le e ntle, ha ho hlokahale kapa kalafo e bonolo kamora ho tjheseletsa, boleng bo phahameng ba seam, ha ho na pores, taolo e nepahetseng, sebaka se senyenyane sa ho tsepamisa maikutlo, ho nepahala ha maemo a holimo, ho bonolo ho fihlella Automation, kahoo e ratoa haholo ke basebelisi, ha e ntlafatse feela katleho ea tlhahiso le ts'ebetso, empa hape e fokotsa mosebetsi o boima o latelang oa ho sebetsa.

Indasteri ea tjheseletsa ea laser

Indasteri ea likoloi, indasteri ea hlobo, indasteri ea bongaka, indasteri ea mabenyane, joalo-joalo.

Mofuta oamochine oa ho tjheseletsa laser

1.Fiber laser welding machine-Handheld Type

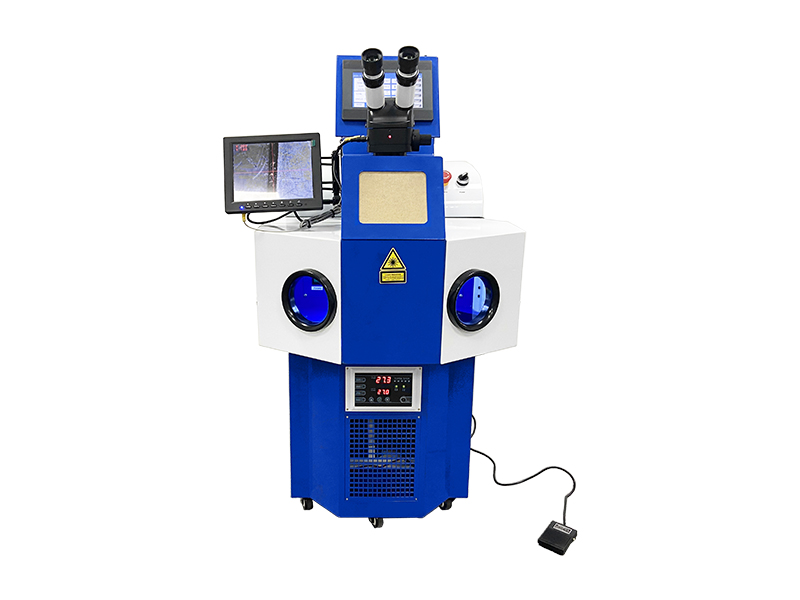

2.Mold laser welding machine- Manual Type

3.Cantilever laser welding machine-Ka letsoho le botsoa

4.3-Axis laser welding mochini-Mofuta o ikemetseng

5.Mabenyane a laser welding mochini-Mofuta oa Desktop

6.Mabenyane a laser tjheseletsa mochini-Inbuilt Water Chiller

7.Mabenyane a laser welding mochini-Arohaneng Water Chiller

Mehlala:

Nako ea poso: Apr-27-2023