Laser welding ke mokhoa oa ho tjheseletsa o sebelisetsoang ho kopanya likotoana tse ngata tsa tšepe ka ho sebelisa lebone la laser.Sistimi ea welding ea laser e fana ka mohloli o matla oa mocheso, o lumellang litšepe tse moqotetsane, tse tebileng le litheko tse phahameng tsa welding.Ts'ebetso ena e sebelisoa khafetsa lits'ebetsong tsa li-welding tse phahameng, joalo ka indastering ea likoloi.

Laser welding e potlakisa ts'ebetso ea ho nkela likarolo tsa fored sebaka ka likarolo tse hatisitsoeng.Laser welding e sebelisetsoa ho nkela li-welds tsa discrete sebaka ka li-welds tse tsoelang pele tsa laser, tse ka fokotsang bophara ba ho fetana le likarolo tse ling tse matlafatsang, 'me li ka hatella molumo oa sebopeho sa' mele ka boeona.Ka lebaka leo, boima ba 'mele oa koloi bo ka fokotsoa ka 56kg.Tšebeliso ea laser welding e fihletse phokotso ea boima ba 'mele le phokotso ea moea, e fihlelang litlhoko tsa ts'ireletso ea tikoloho mehleng ea kajeno.

Ho tjheseletsa ka laser ho sebelisoa bakeng sa ho tjheseletsa ha lipoleiti tsa botenya tse sa lekanang, 'me melemo e bohlokoa haholo.Theknoloji ena e fetola mokhoa o tloaelehileng oa tlhahiso-pele oa ho hatakela likarolo, 'me joale ho tjheseletsa sebakeng se feletseng: pele ho tjheseletsa likarolo tse' maloa tse nang le botenya bo fapaneng ka kakaretso, ebe ho hatakela le ho etsa, ho fokotsa palo ea likarolo le ho sebelisa thepa e eketsehileng.Hoa utloahala, sebopeho le ts'ebetso li ntlafalitsoe haholo.

Mekhoa e fapaneng ea welding ea laser hangata e sebelisoa bakeng sa ho cheselletsa likarolo tse fapaneng tsa 'mele.Lenane le latelang ke lethathamo la mekhoa e mengata ea ho tjheseletsa laser e sebelisoang hangata indastering ea likoloi.

(1) Ho chesoa ka laser

Laser brazing e atisa ho sebelisoa bakeng sa ho hokahanya sekoahelo se ka holimo le lebota le lehlakoreng, sekoahelo sa kutu, joalo-joalo Volkswagen, Audi, Peugeot, Ford, Fiat, Cadillac, joalo-joalo kaofela ba sebelisa mokhoa ona oa ho tjheseletsa.

(2) Laser self-fusion tjheseletsa

Laser self-fusion welding ke ea welding e tebileng ea ho kenella, e sebelisoang haholo-holo bakeng sa marulelo le mahlakoreng a mahlakoreng, mamati a koloi, joalo-joalo. Hona joale, likoloi tse ngata tsa mofuta oa Volkswagen, Ford, GM, Volvo le bahlahisi ba bang ba sebelisa laser self-fusion welding.

(3) Laser remoutu welding

Laser remote welding e sebelisa roboto + galvanometer, sebaka se hole sa beam + welding, 'me molemo oa eona ke ho khutsufatsa haholo nako ea ho beha maemo le katleho e phahameng ha e bapisoa le ts'ebetso ea laser ea setso.

Laser welding e ka boela ea sebelisoa ho li-cigar lighter, li-valve lifter, li-cylinder gaskets, li-injection tsa peterole, li-spark plugs, li-gear, shafts tse ka thōko, li-drive shafts, li-radiator, li-clutch, lipeipi tsa ho qeta enjene, li-axle tsa supercharger, le ho lokisa liner le airbag le ho kopanya likoloi tse senyehileng. likarolo.

Laser welding e na le melemo le melemo e mengata ho feta mekhoa ea khale ea ho tjheseletsa 'me e ka fokotsa litšenyehelo haholo ha e ntse e ntlafatsa katleho ea tlhahiso le boleng.

Laser welding e na le litšobotsi tse latelang:

①Mokhahlelo o moqotetsane oa ho futhumatsa (o tsepamisitsoe).

②Sebaka sa ts'ebetso le boemo li ka laoloa ka nepo.

③ Sebaka se anngoeng ke mocheso se nyane.

④ The deformation ea welding e nyane, 'me ha ho hlokahale tokiso ea kamora ho tjheseletsa.

⑤ Ts'ebetso e sa amaneng le batho, ha ho hlokahale hore u hatelle workpiece le phekolo ea holim'a metsi.

⑥E khona ho hlokomela ho chesetsoa ha thepa e sa tšoaneng.

⑦ Lebelo la tjheseletsa le potlakile.

⑧ Ha ho na tšusumetso ea mocheso, ha ho lerata kapa tšilafalo ho lefatše le kantle.

Mechini e khothalelitsoeng e loketseng ho tjheseletsa koloi ke e latelang:

Mochini oa tjheseletsa oa Laser bakeng sa Mold

Ka nts'etsopele ea indasteri, theknoloji ea welding ea laser e lula e etsoa lipatlisiso le ho nchafatsoa.Hajoale, indastering ea welding ea mochini, mochini o tsebahalang oa welding oa laser o bakoa ke litšobotsi tsa ona tse ikhethang mme o bonts'a litšobotsi tse ntle tsa ts'ebetso nakong ea ts'ebetso ea welding.Kahoo e ka sebelisoa haholo libakeng tse ngata.

Mofuta oa hlobo oa laser welding o bapala karolo ea bohlokoa haholo indastering ea sejoale-joale, 'me boleng ba eona bo supa boleng ba sehlahisoa ka kotloloho.Ho ntlafatsa bophelo ba ts'ebeletso le ho nepahala ha hlobo le ho khutsufatsa potoloho ea tlhahiso ea hlobo ke mathata a tekheniki ao lik'hamphani tse ngata li hlokang ho a rarolla ka potlako.Leha ho le joalo, mekhoa ea ho hlōleha e kang ho oa, ho senyeha, ho apara, esita le ho senya hangata ho etsahala nakong ea tšebeliso ea hlobo.Ka hona, theknoloji ea ho lokisa welding ea laser e boetse e hlokahala bakeng sa ho lokisa hlobo.

Mochini oa welding oa laser ke mofuta o mocha oa mokhoa oa ho tjheseletsa, haholo-holo bakeng sa ho tjheseletsa ha thepa e nang le marako a masesaane le likarolo tse nepahetseng.E khona ho hlokomela tjheseletsa, butt welding, stitch welding, sealing welding, joalo-joalo, e nang le karolo e phahameng ea likarolo, bophara bo nyane ba weld, le sebaka se anngoeng ke mocheso.Nyenyane, deformation e nyane, lebelo le potlakileng la welding, seam e boreleli le e ntle ea welding, ha ho na tlhoko kapa ts'ebetso e bonolo kamora ho tjheseletsa, boleng bo holimo ba seam, ha ho masoba a moea, taolo e nepahetseng, sebaka se senyenyane sa ho tsepamisa maikutlo, ho nepahala ha maemo a holimo, le ho le bonolo ho elelloa automation.

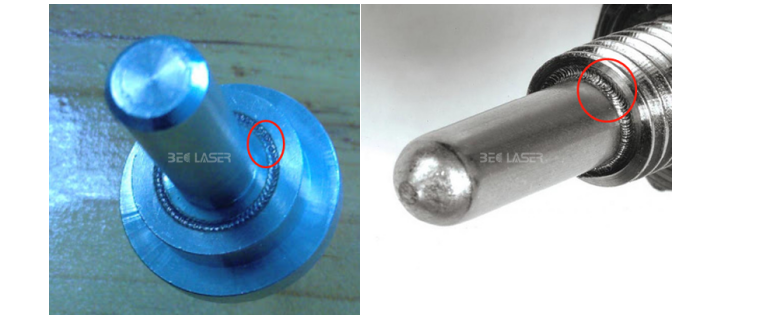

Mohlala o tloaelehileng oa ts'ebeliso ea mochini oa welding oa laser indastering ea hlobo ke mochini o lokisang hlobo oa laser welding.Thepa ena e bonolo ho basebelisi ba ho e sebelisa, e ka eketsa haholo lebelo la ho lokisoa ha welding, 'me phello ea ho lokisa le ho nepahala li haufi le botle, e leng se etsang hore thepa e sebelisoe haholo tšimong ea hlobo ea hlobo.The lokisa tjheseletsa mocheso ameha sebakeng sa mochine ona tjheseletsa e nyenyane haholo, 'me ha ho hlokahale hore futhumatsang esale pele,' me workpiece welded ha e hlahe annealing ketsahalo ka mor'a mosebetsi.Theknoloji ena ea ho lokisa welding ea laser e ke ke ea sebelisoa feela ho lokisa hlobo, empa hape e ka fihlela welding e nepahetseng ea likarolo tse fapaneng tsa 'mele.

Nako ea poso: Jul-15-2021