Mechini ea tjheseletsa ea laserke mokhoa o sebetsang hantle le o nepahetseng oa ho cheseletsa o sebelisang lebone la laser le nang le matla a phahameng joalo ka mohloli oa mocheso.Laser welding ke e 'ngoe ea likarolo tsa bohlokoa tsa ts'ebeliso ea theknoloji ea laser material processing.Lilemong tsa bo-1970, e ne e sebelisoa haholo-holo bakeng sa ho cheselletsa thepa e nang le marako a tšesaane le ho cheselletsa ka lebelo le tlaase.The tjheseletsa tshebetso ke ea mogote conduction mofuta, ke hore, bokaholimo ba workpiece e halefile ka laser mahlaseli, 'me mocheso holim'a diffuses ho hare-hare ka conduction mocheso.Ka ho laola bophara, matla, matla a tlhōrō le ho pheta-pheta maqhubu a laser pulse le likarolo tse ling ho qhibilihisa workpiece le ho theha letamo le khethehileng le qhibilihisitsoeng.Ka lebaka la melemo ea eona e ikhethang, e 'nile ea sebelisoa ka katleho ho tjheseletsa ka mokhoa o nepahetseng oa likarolo tse nyenyane le tse nyenyane.

一、 Litšobotsi tsa Welding

Ke ea fusion welding, e sebelisang beam ea laser e le mohloli oa matla ho ama lenonyeletso la weld.

Beam ea laser e ka tataisoa ke ntho e bataletseng ea optical, joalo ka seipone, ebe e hlahisoa holim'a seam ea weld ka ntho e bonts'ang maikutlo kapa seipone.

Laser welding ha e kopane le tjheseletsa, ha ho na khatello e hlokahalang nakong ea ts'ebetso, empa khase ea inert ea hlokahala ho thibela oxidation ea letamo le qhibilihisitsoeng, 'me ka linako tse ling ho sebelisoa tšepe ea ho tlatsa.

Laser welding e ka kopanngoa le MIG welding ho theha laser MIG composite welding ho finyella welding e kholo ea ho kenella, 'me mocheso oa mocheso o fokotsehile haholo ha o bapisoa le oa MIG.

二、Molao-motheo o sebetsang oa mochini oa tjheseletsa oa hlobo

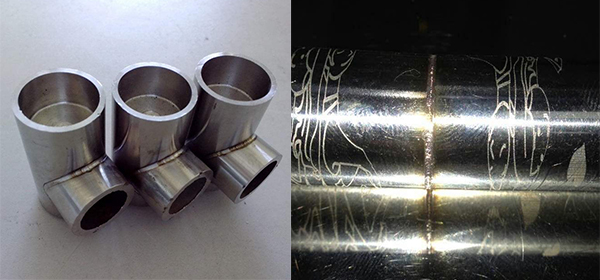

The hlobo laser tjheseletsa mochini e boetse ke lekala lamochine oa ho tjheseletsa laser, kahoo molao-motheo oa ho sebetsa ke ho sebelisa matla a matla a laser pulses ho futhumatsa thepa sebakeng se senyenyane.Matla a mahlaseli a laser a fapana ka har'a thepa ka ho tsamaisa mocheso, 'me thepa e qhibiliha ebe e thehoa.letamo le khethehileng la ho qhibiliha.Ke mofuta o mocha oa mokhoa oa ho tjheseletsa, haholo-holo bakeng sa ho tjheseletsa ha lisebelisoa tse tšesaane tse nang le marako le likarolo tse nepahetseng, 'me o khona ho hlokomela ho tjheseletsa ha letheba, ho tjheseletsa butt, ho tjheseletsa ho tjheseletsa, ho tiisa tjheseletsa, joalo-joalo. seam, ha ho na tlhoko kapa kalafo e bonolo ka mor'a ho tjheseletsa, boleng bo phahameng ba seam, ha ho na li-pores, taolo e nepahetseng, sebaka se senyenyane sa ho tsepamisa maikutlo, ho nepahala ha maemo a holimo, le boiketsetso bo bonolo.Mechini e nang le matla a phahameng a laser e se e thakhotsoe, 'me mekhoa e fapaneng ea mochini oa welding ea laser le litokiso li ka fumaneha bakeng sa lisebelisoa tse teteaneng.

Mohlala:

三、 Litšobotsi tsa hlobo ea laser welding

Mochini oa ho tjheseletsa oa laser hlobo o amohela ponts'o e kholo ea skrineng sa LCD ea China, e nolofaletsang opareitara ho ithuta le ho sebetsa.Thepa e boetse e amohela mosebetsi oa lenaneo la fonte ho hlokomela mosebetsi oa mefuta e mengata, o loketseng ho lokisa hlobo ea thepa e ngata.Hase feela sebaka se amehileng ke mocheso se senyenyane, tekanyo ea oxidation e tlaase, empa hape ho ke ke ha e-ba le li-blister, pores le liketsahalo tse ling.Ka mor'a hore hlobo e lokisoe, phello ea ho lokisoa ke ho se finyelle ho se lekane ha motsoako, 'me e ke ke ea baka ho senyeha ha hlobo.

四、 Configuration le theknoloji ea ho sebetsa

1. hlobomochine oa ho tjheseletsa lasere lokela ho sebelisa microscope ea 10X kapa 15X ho lekola tšebetso.

2. Phepelo ea matla ea mochini oa welding oa laser ea hlobo e ka amohela tšebetso e feto-fetohang ea waveform, e loketseng bakeng sa ho cheselletsa lisebelisoa tse fapaneng.Tse kang: tšepe ea tšepe, tšepe e sa hloekang, koporo ea beryllium, aluminium, joalo-joalo.

3. Ts'ebetso ea CCD (sistimi ea kh'amera) e ka sebelisoa bakeng sa ho beha leihlo, mosebetsi ke: ntle le opareitara e shebileng ho tsoa ho microscope, bao e seng basebetsi ba ka shebella ts'ebetso eohle ea welding ka skrineng sa ponts'o ea sistimi ea khamera, sesebelisoa sena ke molemo ho sa sebetseng Lithupelo tsa botekgeniki tsa basebetsi le lipontšo tsa lipontšo li bile le karolo e ntle ho phahamisetseng thekenoloji ea laser welding.

4. E ka qhibilihisa lithapo tsa ho tjheseletsa tsa bophara bo fapaneng, ho tloha ho 0,2 ho isa ho 0,8 ka bophara.

5. Mochine oa welding laser oa hlobo o tlameha ho sireletsoa ke khase ea argon, 'me lenaneo le lokela ho behoa ho ntša khase ea argon pele ebe laser ho thibela oxidation ea laser ea pele ea pulsed nakong ea ts'ebetso e tsoelang pele.

6. Ha hlobo e le laser welded, ketsahalo e tloaelehileng haholo ke hore ho na le matšoao a ho loma ho potoloha karolo ea welding.Hoa hlokahala ho sebelisa mokhoa oa laser air punching ho koahela liphetoho tse ka bakang matšoao a ho loma ho thibela ho hlaha ha matšoao a ho loma.Ho lekane hore letheba le khanyang le feta moeli oa sebaka sa welding ka 0.1mm.

Nako ea poso: Jun-12-2023