Mochini oa welding oa laser o sebelisa matla a matla a laser pulses ho futhumatsa thepa sebakeng se senyenyane.Matla a mahlaseli a laser a kenella ka hare ho thepa ka ho tsamaisa mocheso, 'me thepa e qhibiliha ho etsa letamo le khethehileng le qhibilihisitsoeng.

Ke mofuta o mocha oa mokhoa oa ho tjheseletsa, haholo-holo bakeng sa ho tjheseletsa ha thepa e tshesaane e nang le marako le likarolo tse ntle, tse ka hlokomelang ho tjheseletsa ha letheba, ho tjheseletsa butt, ho tjheseletsa tjheseletsa, ho tiisa tjheseletsa, jj. mocheso ameha sebaka, Small deformation, lebelo tjheseletsa lebelo, boreleli le e ntle tjheseletsa seam, ha ho hlokahale kapa phekolo e bonolo ka mor'a hore tjheseletsa, phahameng tjheseletsa seam boleng, ha ho pores, taolo e nepahetseng, letheba tse nyenyane tse lebisang tlhokomelo, boemo bo phahameng ho nepahala, ho le bonolo ho hlokomela automation.

1, Mokhoa oa ho khetha mochini o fapaneng oa welding oa laser?

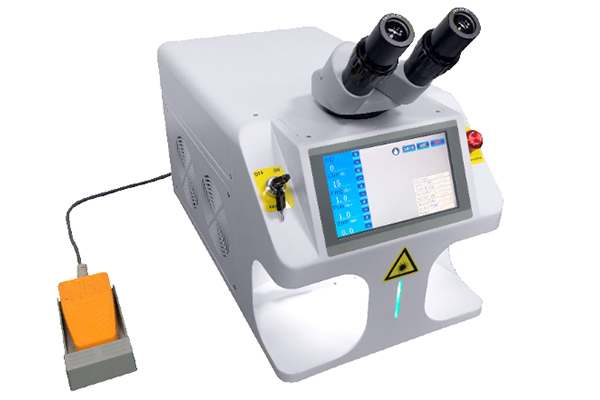

① Mochini oa welding oa laser: o loketse lebenkele la mabenyane.Haholo-holo e sebelisoa ka khauta le silevera kapa mekhabiso e meng ea tšepe ea lesoba le tjheseletso ea letheba.

②Mochini oa welding oa laser: Haholo-holo bakeng sa ho tjheseletsa ha thepa e nang le marako a masesaane le likarolo tse nepahetseng. E khona ho hlokomela welding, butt welding, stitch welding, welding e tiisitsoeng, joalo-joalo, ka tekanyo e phahameng ea likarolo, bophara bo bonyenyane ba weld, sebaka se senyenyane se amehileng ke mocheso. le deformation e nyane.

③Mochini oa welding oa laser o nang le letsoho: O amohela moloko o mocha oa li-laser tsa fiber 'me o na le lihlooho tse phahameng tsa laser welding, tse bonolo haholoanyane bakeng sa lisebelisoa tse fapaneng tsa ho sebetsa.Ts'ebetso e bonolo, seam se setle sa weld, lebelo le potlakileng la welding ebile ha ho na lisebelisoa.

2, Sesebelisoa sa mochini oa ho roala mabenyane a Laser ka mabenyane

Mochini oa ho roala mabenyane oa laser ke setsebi se hloahloa sa ho roala mabenyane.Molao-motheo oa ho sebetsa ke ho thabisa mochine o sebetsang oa laser (o kang motsoako oa CO2 le likhase tse ling, YAG yttrium aluminium garnet crystals, joalo-joalo) ka tsela e itseng.The reciprocating oscillations ka hare ho cavity etsa lehlasedi la mahlaseli stimulated.Ha sefate se kopana le workpiece, matla a eona a kenngoa ke karolo ea mosebetsi, 'me welding e ka etsoa ha mocheso o fihla sebakeng sa ho qhibiliha ha thepa.

Mochini oa ho roala mabenyane a laser: Mochini oa ho roala mabenyane oa laser ke sesebelisoa sa laser se etselitsoeng ka ho khetheha ho roala mabenyane a laser.E sebelisoa bakeng sa ho roala mabenyane a letheba, ho lokisa lesoba, ho lokisa seam, ho hokahanya likarolo, joalo-joalo Ha ho bapisoa le mekhoa ea khale ea ho tjheseletsa, e na le melemo e hlahelletseng joalo ka manonyeletso a manyane le a boreleli, botebo bo tebileng ba welding, ts'ebetso e potlakileng le e bonolo.

Nako ea poso: Jun-19-2023